Solid wood board

The board cut from pure natural wood, natural texture, scratch-resistant and load-bearing, is currently a kind of board with high environmental protection. However, because it is a pure natural plate, the cost is very high, and the price is also the most expensive of all the board panels.

In addition, the density and hardness of solid wood panels are lower than wood-based panels, the nail grip force is poor, the risk of deformation is higher if it use a long time.

Plywood

The veneer or thin wood cut from wood is formed by gluing and hot pressing to form a board, also known as plywood.

Because it is a multi-layer structure itself, it has a stable structure, high hardness and strong bearing capacity. However, the defect is poor toughness, easy to bend and deform, especially when making cabinets with a height of more than 1.5 meters, the longitudinal stretching is too large, and the probability of deformation is very easy.

Particle board

Panels are made of wood or lignocellulose as materials and hot pressed by adhesive. Due to this reason, its production cost is very low, and the board panel has good stability and durability after pressing, so it has become the preferred board for many custom wardrobe brands.

However, the particle board is glued and synthesized, the formaldehyde pollution is inevitable, on the other hand, the formaldehyde problem does not need to be too worried, the formaldehyde emission of the general particle board, as long as it does not exceed the national standard E1 standard, you can buy it without any mind.

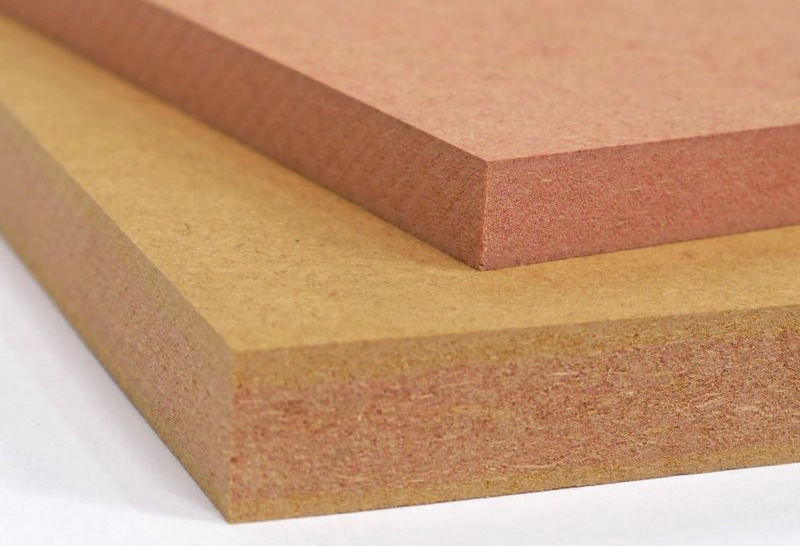

MDF

The synthetic board with wood fiber and glue, it is low in production cost, and the only advantage is good toughness, not easy to deform and crack, and is very suitable for cabinet doors.

Post time: Nov-09-2022